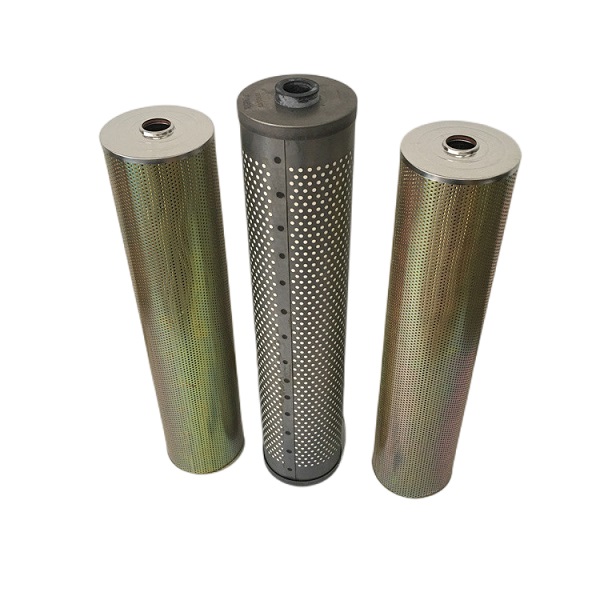

oil regeneration cellulose precision filter

Composition of anti-fuel regeneration device: diatomaceous earth filter and SH006 EH oil regeneration cellulose precision filter

Operation conditions: acid value>0.08 replacements (recommended to be put into operation for 8 hours per week):

1. If the oil temperature of any filter is between 43 and 54°C, and the oil pressure in the cylinder is as high as 0.21MPa, the filter element should be replaced.

2. The diatomaceous earth filter element should be replaced after 48 hours after the regeneration device is put into operation, the acid value of the fire-resistant oil will not decrease or after six months of continuous use. (Before replacement, it is recommended to bake in a 120°C oven for 8 hours or in a 110°C drying oven for 12 hours, and after cooling to 20 ~ 30°C in the oven, put it into the filter cartridge immediately)

Steps to put the regeneration device into operation:

1. Open the corrugated fiber and fill the throttle with oil;

2. Open the diatomaceous earth into the throttle;

3. Close the corrugated fiber into the throttle;

4. Maintain the pressure of the two filters not more than 0.21MPa.

The increase in acid value of the anti-fuel oil system is a typical manifestation of the aging of the oil due to the high temperature and high pressure of the system, and the diatomite filter element should be replaced in time. In order to prevent the contamination of the oil by the diatomite filter element, the SH006 EH oil regeneration cellulose precision filter should be replaced at the same time.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur