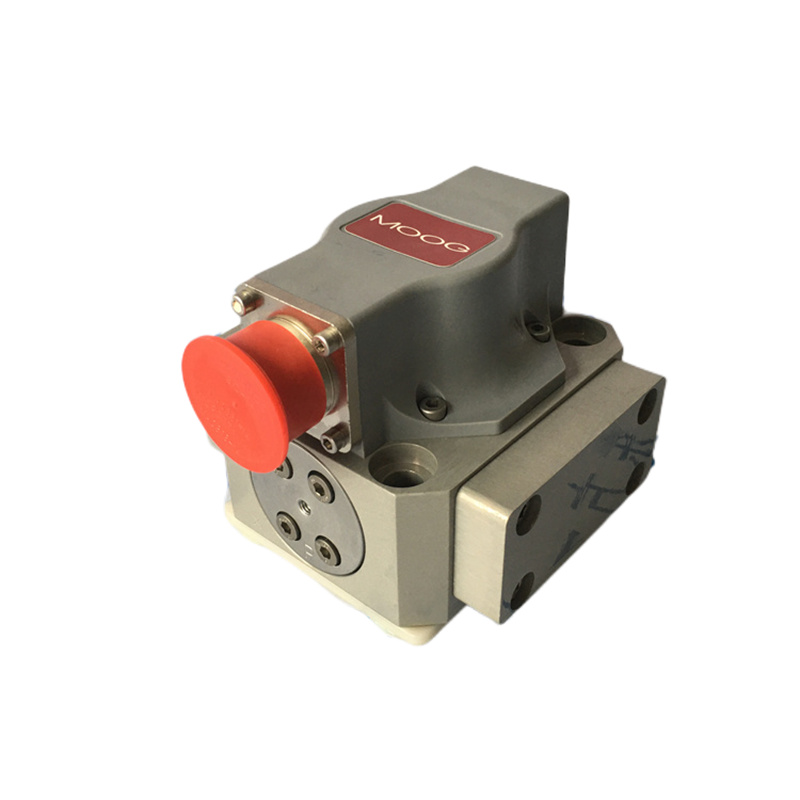

actuator electro-hydraulic servo valve

An SM4 servo valve, when used with a hydraulic cylinder, position transducer, and appropriate electronics, can provide infnite cylinder position control to within 0,025mm (0.001 in) or better, depending on the components selected, length of stroke, and load characteristics

When applied with servo hydraulic motors using tachometer feedback and appropriate electronics, the SM4-20(15)57-80/40-10-S182 actuator electro-hydraulic servo valve provides infnite proportional flow control for real-time velocity/acceleration profles. The resulting closed loop system can be error corrected to within one-tenth of a revolution per minute. With appropriate pressure transducers or load cells in force control applications, the SM4 makes possible exact load pressure/force control. In addition, excellent system stability with pressure and load to ±1% full scale can be achieved.

Features and Benefts

• The wide range of servo valve SM4-20(15)57-80/40-10-S182 flow capabilities allows selection of the valve size best suited for an application

• The high strength aluminum alloy of the second stage valve body means lighter weight with rugged durability.

• Higher frequency response is available on request to provide enhanced system bandwidth for critical performance requirements.

• The spool and sleeve are hardened stainless steel to minimize wear and erosion. The O-ring mounted sleeve eliminates spool binding and ensures smooth operation.